About belt alignment

Belt alignment tools

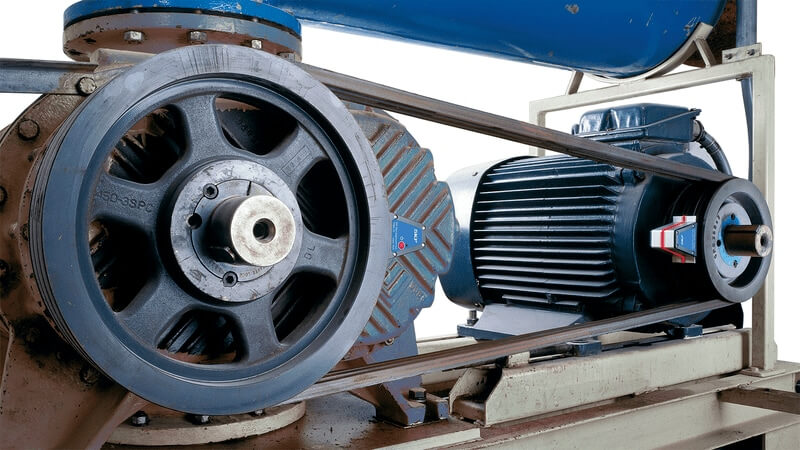

SKF offers a range of belt alignment tools to ensure correct alignment for virtually any application.

One of the common causes of unscheduled downtime of belt-driven machines is pulley misalignment. Pulley misalignment can increase wear on pulleys and belts, as well as increase noise and vibration levels, resulting in unplanned machine downtime. Another side effect of increased vibration is premature bearing failure. This can cause unplanned machine downtime.

Traditional belt alignment methods

These most commonly used methods involve either using visual judgment alone or using visual judgment in combination with straight edge and/or string length. The advantage of these traditional methods is the perceived short time required for adjustment, although the use of straight edges takes more time than visual evaluation alone. The biggest drawback is the lack of accuracy. Some belt manufacturers recommend a maximum horizontal angle shift of 0.5° or even 0.25°, which is impossible to achieve with the naked eye.

Measuring parallel (A) and angular (B) misalignment using a straight edge or a piece of string (C).

Correct alignment means the grooves of the pulleys are aligned (D)

Laser belt alignment methods

Using a laser belt alignment tool is faster and more accurate than traditional methods. Belt alignment tools can align pulley surfaces or pulley grooves.

SKF has three belt alignment tools that can be categorized as in-groove alignment or flank alignment.

Alignment in the groove rather than the surface of a V-belt pulley ensures optimum alignment of pulleys of unequal width or different faces.

Percent alignment is more versatile. It can be used on almost any machine that uses V-belts, belt belts, ribbed belts and many other belts as well as sprockets.

Correct pulley and belt alignment can help you:

- Increase bearing life

- Increase machine uptime, efficiency and productivity

- Reduce wear on pulleys and belts

- Reduce friction and therefore energy consumption

- Reduce noise and vibration

- Reduce component replacement costs and machine downtime

A.Vertical angle misalignment

B.Horizontal angle misalignment

C.Parallel alignment error

D.Correct alignment